Dual V guide wheel

V Guide Wheels are the main components of the Linear Motion System, they can be widely used in the industrial robot, cutting machine, motion track, production flow and so on.

- Description

- Specification

- Application

- Cross No.

Features

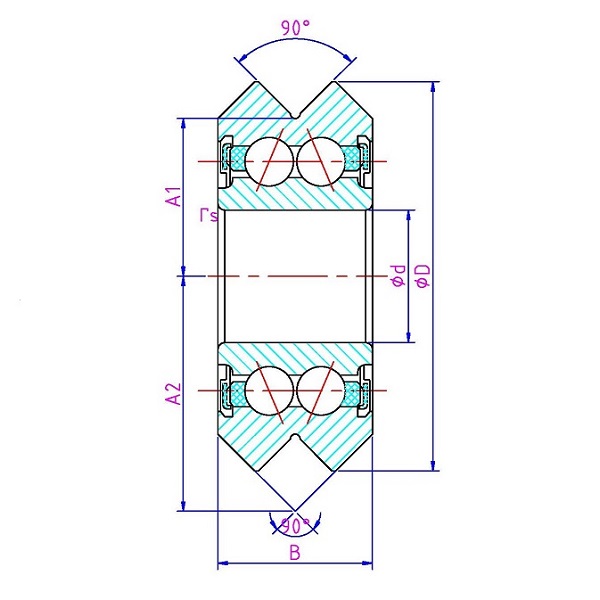

• dual v guide wheel based on double row angular contact ball design,the thicker outer rings with "W" profile

• AISI 52100 (100Cr6) steel or stainless steel AISI 440 C ( DIN 1.14304)

• Nylon cage with fiberglass fill 25%

• Lubricant-Shell Alvania RLS2 grease

• SPCC shields or acrylonitrile-butadiene steel sheet reinforced (NBR) seals

• Nylon cage with fiberglass fill 25%

• Lubricant-Shell Alvania RLS2 grease

• SPCC shields or acrylonitrile-butadiene steel sheet reinforced (NBR) seals

| C&H No. | Dimensions (mm) | Load Ratings(N) | Mass | ||||||

| d | D | B | A1 | A2 | rs | Radial | Axial | ≈(g) | |

| W0 | 4.763 | 19.56 | 7.87 | 7.93 | 11.86 | 0.3 | 1260 | 297 | 11 |

| W1 | 4.763 | 19.56 | 7.87 | 7.93 | 11.86 | 0.3 | 1260 | 297 | 11 |

| W2 | 9.525 | 30.73 | 11.1 | 12.7 | 18.24 | 0.3 | 2730 | 632 | 38 |

| W3 | 12 | 45.72 | 15.88 | 19.05 | 26.98 | 0.6 | 6160 | 1448 | 130 |

| W4 | 15 | 59.94 | 19.05 | 25.4 | 34.93 | 1 | 9990 | 2310 | 280 |

| W4L | 22 | 75.39 | 25.4 | 31.75 | 44.45 | 1.1 | 1480 | 660 | 580 |

1. Available with shields ( suffix " ZZ " ) and NBR seals ( suffix " 2RS ")

2. Available with stainless steel ( prefix " SS " )

3. Bore ID tolerance is +0-0.008, except W4L. W4L Bore ID tolerance is +0-0.01.

4. Width tolerance is +0-0.12.

5. Clean Room Compatible – All stainless steel components can be internally lubricated with Krytox GPL 227.

6. High Temperature Compatible – Heat stabilized components allow for operating temperatures to 260°C.

| C&H | Desciption | Dimensions (mm) | Load Ratings(KN) | Mass | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| d | D | B | A1 | A2 | rs | Cw | Cow | ≈(kg) | ||

| W0 ZZ | doule shields | 4 | 14.84 | 6.35 | 5.94 | 9.12 | 0.3 | 1 | 0.5 | 0.005 |

| W1 ZZ | doule shields | 4.763 | 19.56 | 7.87 | 7.93 | 11.86 | 0.3 | 2.2 | 1 | 0.011 |

| W2 ZZ | doule shields | 9.525 | 30.73 | 11.1 | 12.7 | 18.24 | 0.3 | 4.9 | 2.5 | 0.035 |

| W3 ZZ | doule shields | 12 | 45.72 | 15.88 | 19.05 | 26.98 | 0.6 | 9.4 | 4.9 | 0.13 |

| W4 ZZ | doule shields | 15 | 59.94 | 19.05 | 25.4 | 34.93 | 1 | 14.8 | 8.2 | 0.28 |

| W4L ZZ | doule shields | 22 | 75.39 | 25.4 | 31.75 | 44.45 | 1.1 | 29.7 | 20 | 0.58 |

| W0 2RS | doule seals | 4 | 14.84 | 6.35 | 5.94 | 9.12 | 0.3 | 1 | 0.5 | 0.005 |

| W1 2RS | doule seals | 4.763 | 19.56 | 7.87 | 7.93 | 11.86 | 0.3 | 2.2 | 1 | 0.011 |

| W2 2RS | doule seals | 9.525 | 30.73 | 11.1 | 12.7 | 18.24 | 0.3 | 4.9 | 2.5 | 0.038 |

| W3 2RS | doule seals | 12 | 45.72 | 15.88 | 19.05 | 26.98 | 0.6 | 9.4 | 4.9 | 0.13 |

| W4 2RS | doule seals | 15 | 59.94 | 19.05 | 25.4 | 34.93 | 1 | 14.8 | 8.2 | 0.28 |

| W4L 2RS | doule seals | 22 | 75.39 | 25.4 | 31.75 | 44.45 | 1.1 | 29.7 | 20 | 0.58 |

| SW0 2RS | stainless steel | 4 | 14.84 | 6.35 | 5.94 | 9.12 | 0.3 | 1 | 0.5 | 0.005 |

| SW1 2RS | stainless steel | 4.763 | 19.56 | 7.87 | 7.93 | 11.86 | 0.3 | 2.2 | 1 | 0.011 |

| SW2 2RS | stainless steel | 9.525 | 30.73 | 11.1 | 12.7 | 18.24 | 0.3 | 4.9 | 2.5 | 0.038 |

| SW3 2RS | stainless steel | 12 | 45.72 | 15.88 | 19.05 | 26.98 | 0.6 | 9.4 | 4.9 | 0.13 |

| SW4 2RS | stainless steel | 15 | 59.94 | 19.05 | 25.4 | 34.93 | 1 | 14.8 | 8.2 | 0.28 |

| SW4L 2RS | stainless steel | 22 | 75.39 | 25.4 | 31.75 | 44.45 | 1.1 | 29.7 | 20 | 0.58 |

V wheels are the main components of the Linear Motion System, they can be widely used in the industrial robot, cutting machine, motion track, production flow and so on.V-wheels can be used with internal or external 90-degree ways, or used with round shafts.Typical application:

|

• Machine tool doors • Vending machines • Woodworking machinery • Carpet and textile machinery • Laboratory automation • Paper converting equipment • Packaging machinery |

|

| C&H | BWC | NIKO | SCHATZ | PBC |

| W0-ZZ | W0 | |||

| W1-ZZ | W1 | RM 1 2Z | W1FF | VW1 |

| W2-ZZ | W2 | RM 2 2Z | W2FF | VW2 |

| W3-ZZ | W3 | RM 3 2Z | W3FF | VW3 |

| W4-ZZ | W4 | RM 4 2Z | W4FF | VW4 |

| W4L-ZZ | W4L | |||

| W0-2RS | W0X | |||

| W1-2RS | W1X | RM 1 2RS | W1LL | VWS1 |

| W2-2RS | W2X | RM 2 2RS | W2LL | VWS2 |

| W3-2RS | W3X | RM 3 2RS | W3LL | VWS3 |

| W4-2RS | W4XXL | RM 4 2RS | W4LL | VWS4 |

| SSW0-2RS | W0SSX | |||

| SSW1-2RS | W1SSX | W1LLSS | VWSS1 | |

| SSW2-2RS | W2SSX | W2LLSS | VWSS2 | |

| SSW3-2RS | W3SSX | W3LLSS | VWSS3 | |

| SSW4-2RS | W4SSX | W4LLSS | VWSS4 | |

| SSW4L-2RS | W4SSXXL |